Used in-line as a non return valve to stop fluids flowing back through your system.

| Model | BSP thread | Metric* |

|---|---|---|

| HCV25 | 1" | 25mm |

| HCV32 | 1 1/4" | 32mm |

| HCV40 | 1 1/2" | 40mm |

| HCV50 | 2" | 50mm |

| HCV63 |

2 1/2" |

63mm |

*Approx BSP Equivalent

See chart below for which size valve to choose

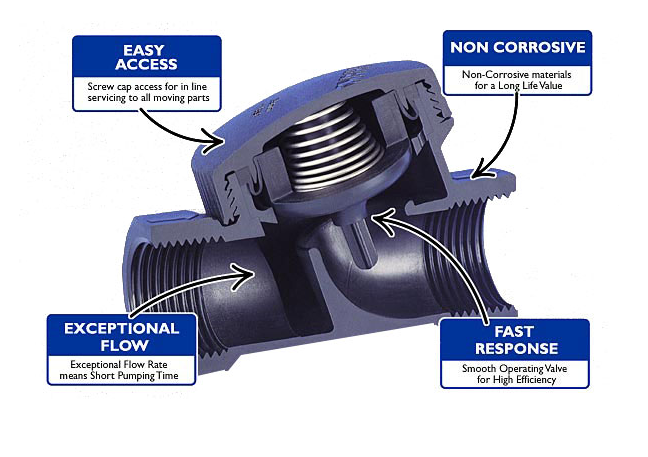

Valve Operation

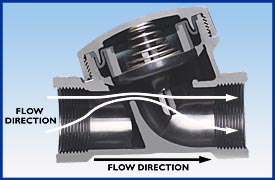

Top: Cross section shows valve in fully open position

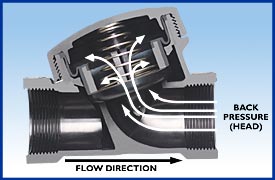

Bottom: Cross section shows valve in fully closed position

When fluid is required in the direction of flow, the diaphragm opens allowing exceptional flow. As the flow through the valve stops, the diaphragm closes preventing any return flow. The greater the back or head pressure, the better the diaphragm seals against the valve seat.

- Exceptional Flow - Move more water in less time.

- Strong Non-Corrosive Materials - Body; High Quality Glass Fibre Reinforced Nylon, Diaphragm; Nitrile Rubber, Spring; Stainless Steel. All components of this valve manufactured from materials approved for use with potable (drinkable) water.

- Inline Servicing - Removable cap - Easy access to all moving parts - Valve stays inline for servicing (if required).

- No poppet valve to wear or jam - Smooth Flow.

- Interchangeable Components - Diaphragm and Spring are Interchangeable Components used in the same size Foot Valve.

- Fast Response Opening & Closing.

- Operates at any angle.

- Maximum Recommended Working Pressure - 10 Bar (1000 kPa. 145 PSI) @ 20°C.

- When screwing metal products into valve, do not over tighten. All pipe work must be adequately supported.